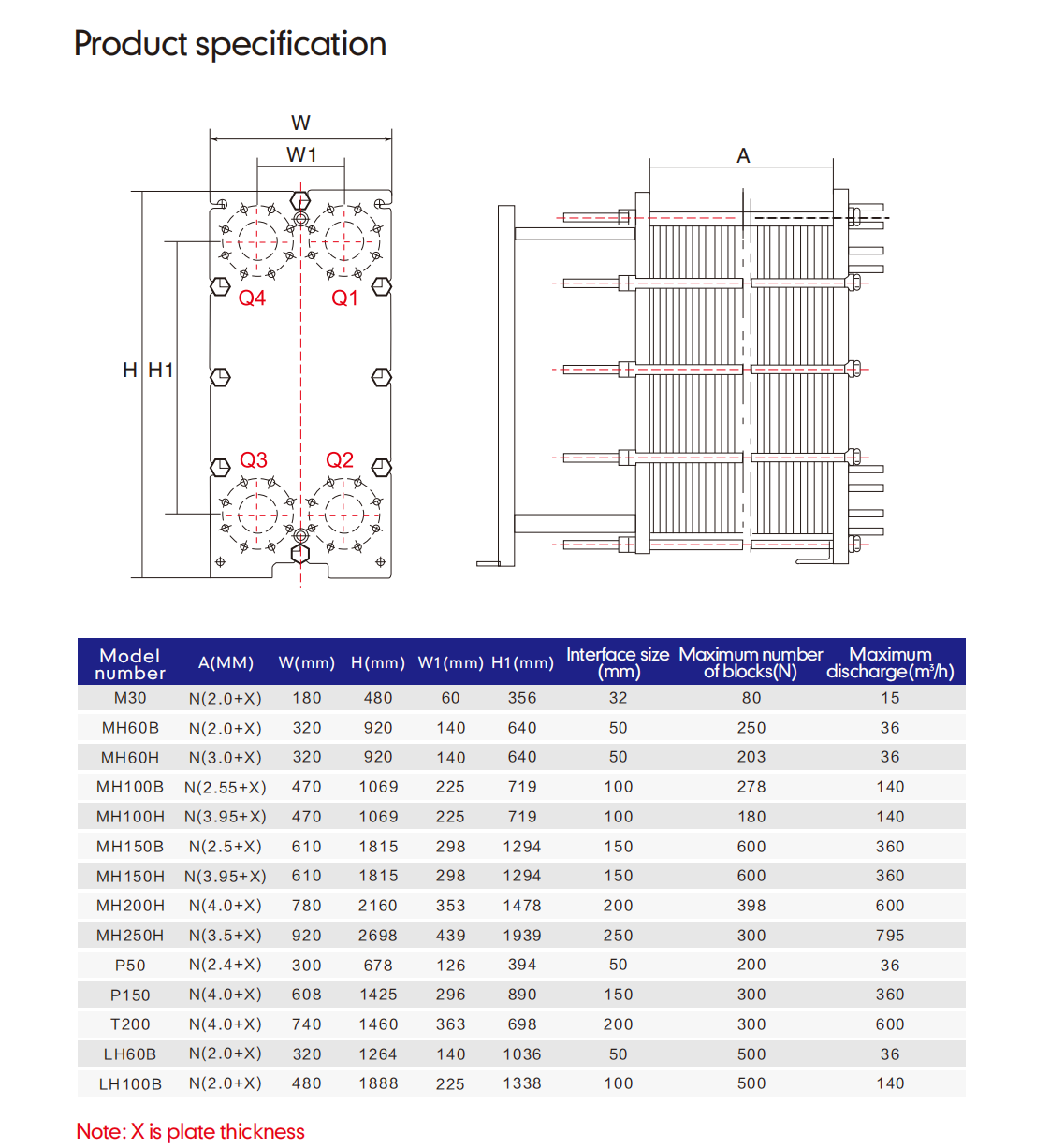

The MB60B-20D-EPDM-304 model produced by our company is a

Detachable Plate Heat Exchanger, the main parameters are 920mm height, 320mm width, the height between the aperture is 640mm, the width between the aperture is 140mm, and the thickness is (2+X)*N, N is the number of plates X is the thickness of a single plate. The maximum connection size is 2 inches! ? High energy efficiency, low operating costs, flexible configuration – modifiable heat exchange area, easy installation, compact design, high maintainability – easy to open for inspection and cleaning, easy to clean. Every detail has been carefully designed to ensure optimal performance, maximum uptime, and ease of maintenance. Choose the available features based on the configuration, suitable for many types of applications, and choose from a variety of plate and gasket types.

The detachable Plate Heat Exchanger is made of many stamped corrugated sheets at certain intervals, sealed by gaskets around the perimeter, and overlapped and pressed by the frame and the compression spiral, the four corner holes of the plate and the gasket form the distribution pipe and the collection tube of the fluid, and at the same time, the cold and hot fluids are reasonably separated, so that they flow in the flow channel on both sides of each plate respectively, and the heat exchange is carried out through the plates.How it worksA plate Heat Exchanger consists of a set of metal plates with four corner holes for both hot and cold media to pass through. During assembly, plate A and plate B are arranged alternately, a network channel is formed between the plates, and the sealing gasket seals the cold and hot medium in the heat exchanger, and at the same time, the cold and hot medium are reasonably separated without mixing. The hot and cold fluids flow at intervals in the channel, which can be reversed or downstream as needed, and the hot and cold fluids are exchanged through the plate wall during the flow process, so as to achieve the desired effect.Design features:1. High efficiency and energy saving: its heat exchange coefficient is 3000~4500kcal/m2·°C·h, which is 3~5 times higher than the thermal efficiency of Shell And Tube Heat Exchanger.2. Compact structure: the plates of the plate heat exchanger are closely arranged, compared with other types of Heat Exchangers, the floor area and space occupied by the plate heat exchanger are less, and the plate heat exchanger with the same area for heat exchange is only 1/5 of the shell and Tube Heat Exchanger.3. Easy to clean and easy to disassemble and assemble: the plate heat exchanger clamps the clamping plate by the clamping bolt, so it is easy to disassemble and assemble, and can be opened and cleaned at any time.4. Long service life: the plate heat exchanger is pressed with stainless steel or titanium alloy plates, which can withstand various corrosive media, and the rubber pad can be replaced at will, and can be easily disassembled, assembled and repaired.5. Strong adaptability: the plate heat exchanger plate is an independent element, which can be added or decreased at will according to the requirements, and the form is diverse; It can be adapted to a variety of different process requirements.6. No liquid stringing, the sealing tank of the plate heat exchanger is set up with a leakage channel, and all kinds of media will not collude, even if there is leakage, the medium is always discharged outward.applyPlate Heat Exchangers have been widely used in metallurgy, mining, petroleum, chemical industry, electric power, medicine, food, chemical fiber, papermaking, textile, shipbuilding, heating and other departments, and can be used for heating, cooling, evaporation, condensation, sterilization and disinfection, waste heat recovery and other situations. The advantages of brazed plate heat exchangers mainly include the following aspects:

High heat transfer efficiency: Brazed plate heat exchangers significantly improve heat transfer efficiency by increasing the heat exchange surface area. Compared to traditional shell-and-tube heat exchangers, brazed plate heat exchangers transfer heat more efficiently, saving energy costs.

Compact design: Due to their parallel plate construction, brazed plate heat exchangers are usually compact and take up less space. This is an important advantage for limited industrial sites and also reduces the cost of the equipment.

Suitable for multi-fluids: Brazed plate heat exchangers can handle many different fluid combinations and are suitable for a variety of process needs. Different fluids can flow independently between plates, avoiding cross-contamination and helping to maintain product quality.

Corrosion resistance: Brazed plate heat exchangers are usually made of stainless steel, copper or other corrosion-resistant materials, which can handle corrosive media and improve the service life of the equipment.

High temperature and high pressure resistance: This metal material determines that the

Brazed Plate Heat Exchanger has the characteristics of high temperature resistance (up to 20°C) and pressure resistance (working pressure up to 30 bar, reinforced type up to 45 bar). Low cost: Brazed plate heat exchangers save material costs compared to general heat exchangers, and save installation space, reducing the overall design cost 2Easy to install: The brazed plate heat exchanger has a variety of fixing methods and is easy to install2Suitable for low-temperature applications: The compact design and high thermal efficiency of brazed plate heat exchangers make them particularly suitable for low-temperature applications. It enables efficient heat transfer in a relatively small space, reducing energy consumption by 3Maintainability: Due to its simple design, it is relatively easy to maintain and clean brazed plate heat exchangers. Users can regularly inspect and clean the plates to ensure their long-term efficient operation.

The advantages of brazed plate heat exchangers mainly include the following aspects:

High heat transfer efficiency: Brazed plate heat exchangers significantly improve heat transfer efficiency by increasing the heat exchange surface area. Compared to traditional shell-and-tube heat exchangers, brazed plate heat exchangers transfer heat more efficiently, saving energy costs.

Compact design: Due to their parallel plate construction, brazed plate heat exchangers are usually compact and take up less space. This is an important advantage for limited industrial sites and also reduces the cost of the equipment.

Suitable for multi-fluids: Brazed plate heat exchangers can handle many different fluid combinations and are suitable for a variety of process needs. Different fluids can flow independently between plates, avoiding cross-contamination and helping to maintain product quality.

Corrosion resistance: Brazed plate heat exchangers are usually made of stainless steel, copper or other corrosion-resistant materials, which can handle corrosive media and improve the service life of the equipment.

High temperature and high pressure resistance: This metal material determines that the brazed plate heat exchanger has the characteristics of high temperature resistance (up to 20°C) and pressure resistance (working pressure up to 30 bar, reinforced type up to 45 bar). Low cost: Brazed plate heat exchangers save material costs compared to general heat exchangers, and save installation space, reducing the overall design cost 2Easy to install: The brazed plate heat exchanger has a variety of fixing methods and is easy to install2Suitable for low-temperature applications: The compact design and high thermal efficiency of brazed plate heat exchangers make them particularly suitable for low-temperature applications. It enables efficient heat transfer in a relatively small space, reducing energy consumption by 3Maintainability: Due to its simple design, it is relatively easy to maintain and clean brazed plate heat exchangers. Users can regularly inspect and clean the plates to ensure their long-term efficient operation.